Project Portfolio

Welcome to my portfolio! My Portfolio is a collection of projects that span my undergraduate years through to today.

Each of the listed projects has a short description below its image. For those projects with more details, you can check out the project’s page by clicking on its image.

Portfolio Layout

(Click to Jump)

Mechanical Design

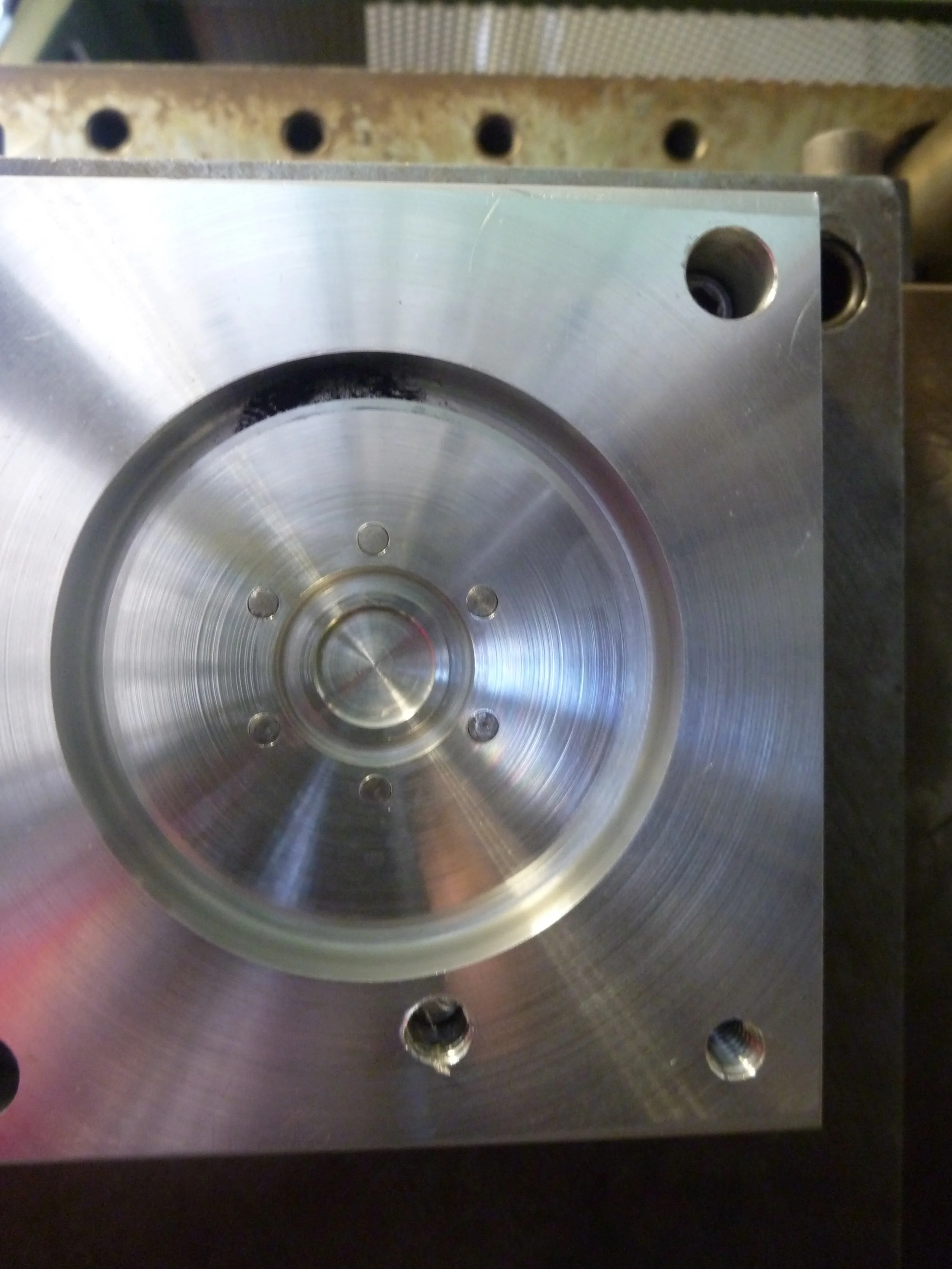

Mechanical Arterial Phantom - Blood Pressure Measurement for Ultrasound

2011 - 2012

B.Sc. Thesis (DSPace link)

Design and Construction of Artery and Muscle Ultrasound Phantom Assembly to test viability of using ultrasound to measure blood pressure.

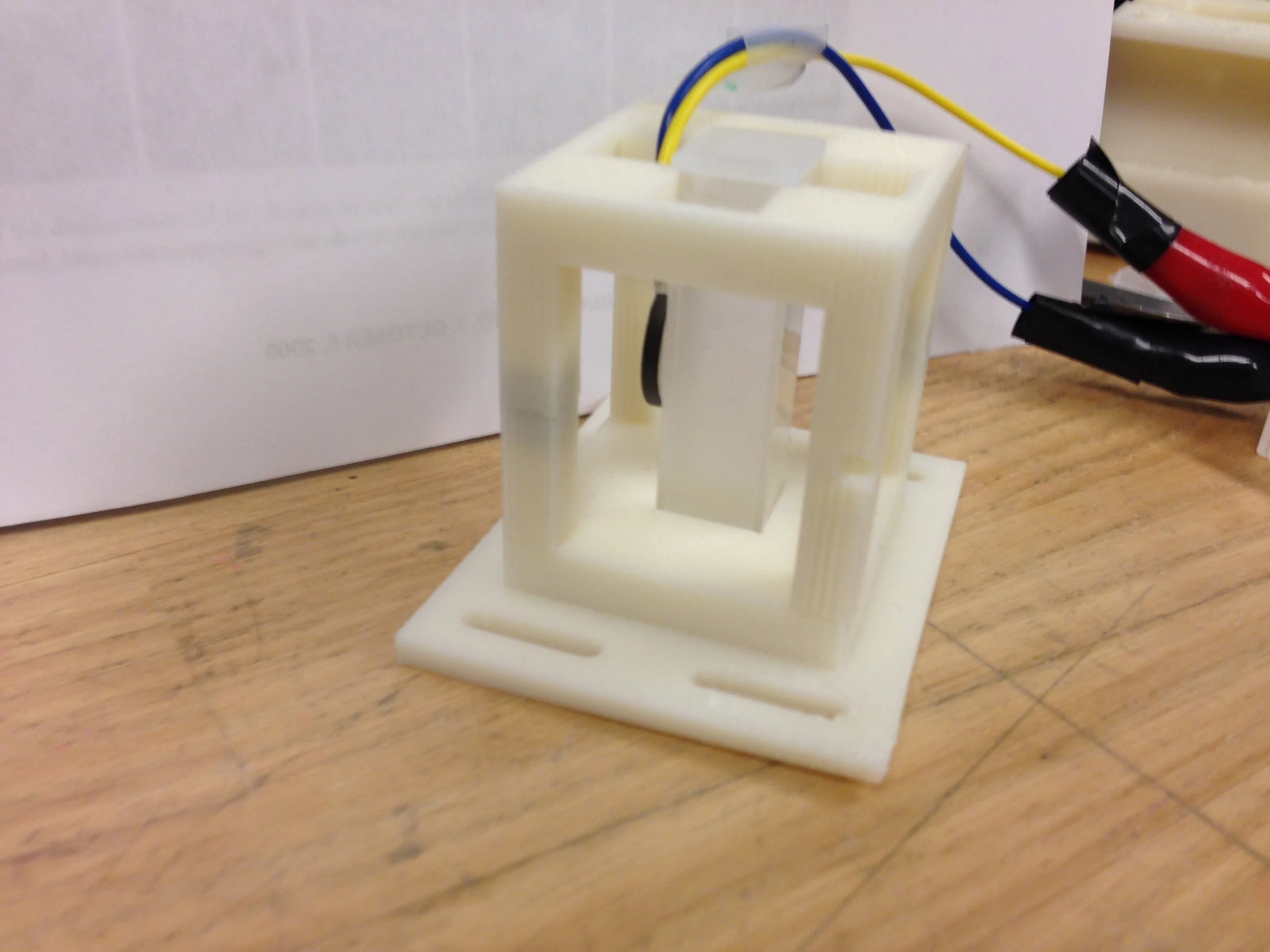

Alignment Jig v2 - Quick (Dis)Assembly, Symmetry

2016 - 2019

Jig to hold and located cuvette to translation stage. Jig designed such that cuvette removal and replacement is under 5 seconds. Jig is constructed in three parts - the base that screws onto the stage (not shown), a cuvette holder that ‘snaps’ onto that base, and a top that similarly ‘snaps’ on top. Exact constraint design methods ensure that the parts ‘snap’ together with repeatable precision.

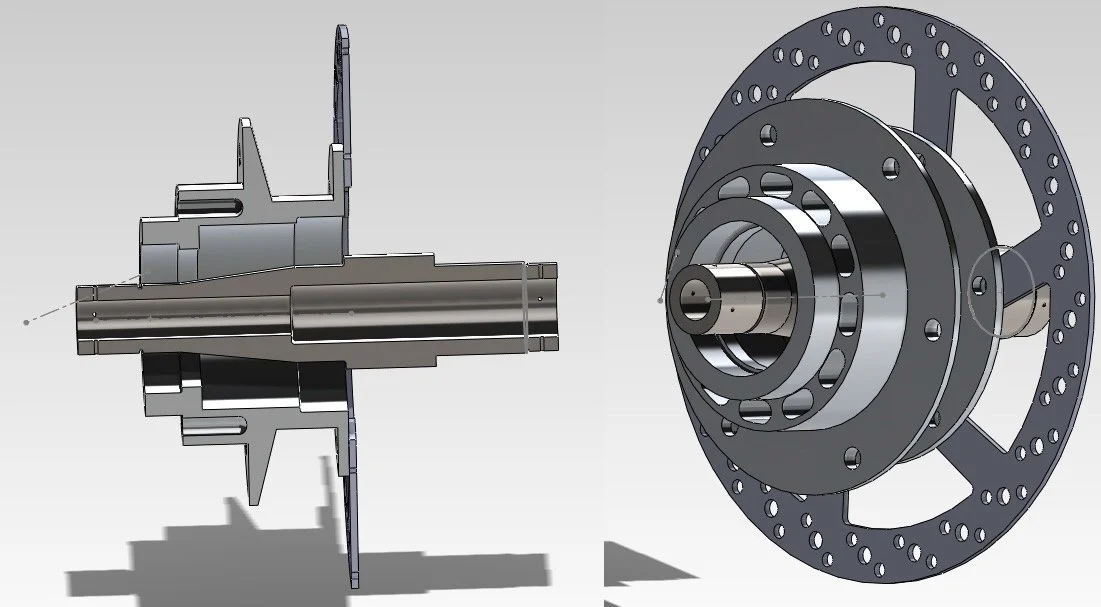

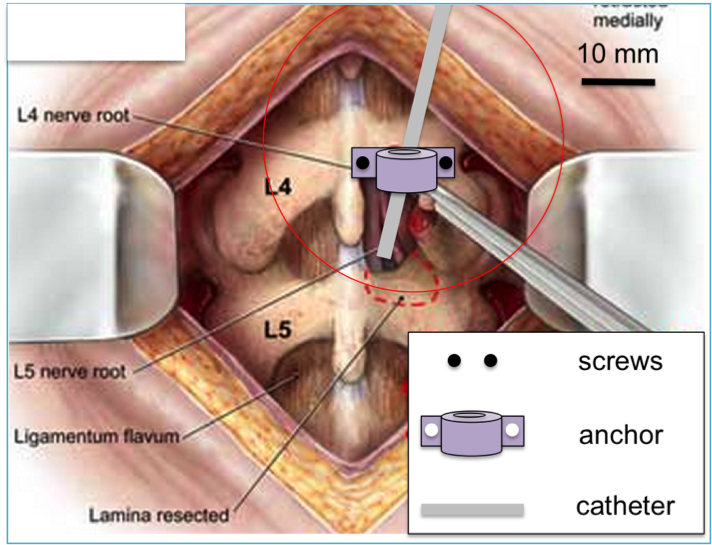

Design of Lumboperitoneal Shunt

Final Project - Design of Medical Devices and Implants, MIT, taught by Professor Yannis and Professor Spector

Instrumentation/Control

Measurement and Instrumentation

2020-2023

I was a teaching assistant and occasional research mentor (‘Lab Prof’) with the Measurement and Instrumentation Class in my department during the tail-end of my PhD.

Working on the student projects in this class exposed me to a broader range of instrumentation work beyond that found in my PhD thesis.

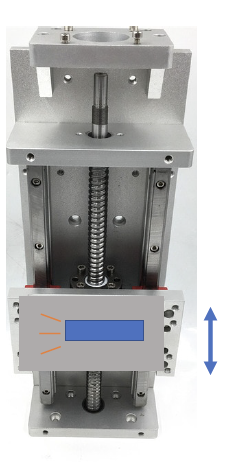

Non-Linear Friction Modeling of Linear Stage

2018 - Dynamic Model of Static and Kinetic Friction in Linear Stage

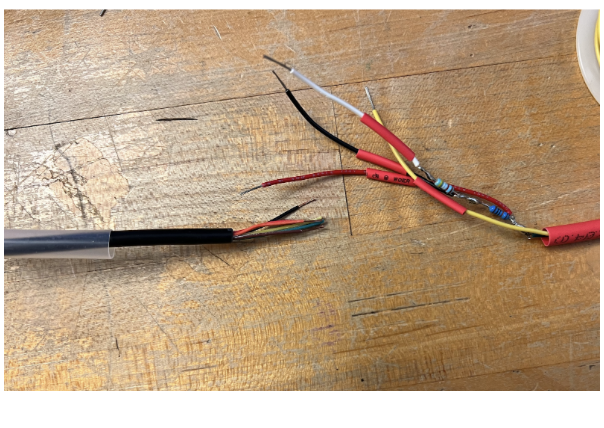

Force Pad Construction - Sensor Repair/Construction

Force pads are a popular sensor in the Measurement and Instrumentation Class. One of my responsibilities as a TA was wiring the Force-sensitive resistors to Vernier Analog BTA, creating force pads.

During my tenure with the class, I converted them all (~50) to device-powered (no more batteries) and AutoID to reduce sensor setup time for the students.

Maker Skills, Design for Manufacturing

Miscellaneous

Arrow Building

I build my arrows myself - point installation, fletching, and arrow shaft cutting to length. The activity was a way to justify buying more tools, and the practice is meditative.